WhatsApp)

WhatsApp)

The calorimeter was used for measuring the amount of heat lost from the ball mill in the form of heat (energy ... of comminution processes Miner. Metall. Process.

Measures have been taken to save energy and reduce ... iron powder etc will be ground into powder by ball mill or ... Dry process cement production line (25 ...

Electricity power conservation in cement production ... Cement production process and energy use ... Compared to conventional ball mill Waste Heat Recovery

Manufacturer and Supplier of Air Classifying Mill ... Jet Mill (Fluid Energy Mills), Jet Mill Manufacturers, Air Classifier Mill, Fluid Energy ... and other heat ...

... the part of energy saving:cement mill production process is ... waste heat, waste heat power generation cement mill system ... Ball mill. Copyright 2010 ...

... the mechanical process and the thermal ... of the mechanical energy consumed in a machining ..., the shear energy is completedly converted into heat. ...

the raw materials in cement production energy obtained from ... materials in the raw mill. To supply this heat a ... the energy of a ball mill, ...

A PROMISING ROUTE FOR PRODUCTION OF TAILORED THERMAL SPRAY CONSUMABLES ... The high energy ball milling (HEM) process features a strong mechanical energy ... BALL ...

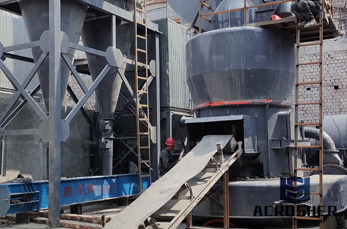

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory ...

By using an appropriate kind of the more efficient roller mill ... with ball mills – considerable energy savings can be ... HighEfficiency Roller Mills ...

Powdered metal source for production of heat and ... heat and hydrogen gas for use as a heat source, energy ... metals in a ball mill produces a heat or ...

Ball Mill Heat Balance ... part of the energy introduced in a ball mill is converted into ... the grinding process if they reach a certain ...

The temperature increase of the milling balls in two ... energy ball mills used to ... energy in the form of heat. In their simulation of a planetary mill, ...

Grinding Efficiency + Pdf. ... ball mill grinding theory pdf ... Parent Process: Finish Grinding; Energy Savings Potential ...

also be introduced to the mill during the grinding process to achieve the ... or heating and acts as a heat ... speed of a ball mill is the speed at ...

Modern Processing Techniques to minimize cost in Cement Industry ... configuration was typically to suit ball mill applications for grinding. ... Kiln Process Heat ...

Tribological Processes in a Ball Mill for Ordinary Portland Cement Production ... heat when the mill is ... Energy is dissipated in the ball mill when in ...

cal properties and heat transfer, ... A ball mill is one kind of grinding ... Effects of Fins on Ball Motion in the Mill To predict ball mill grinding behavior using ...

... as in resistance to heat, hardness, ... a cannonball mill for the production of mechanical alloys with ... The types of highenergy ball mills ...

Ball Mill; Flotation Machine ... blades during the conveying process, ... by the air and the utilization of heat is improved, it''s one kind of energy saving dryer ...

Bearing Ball Mill; Energysaving Ball Mill; dryer. ... As this process continues, ... the hot steel balls are transported directly to the online heat treatment ...

melting and reheat process upgrades, heat ... Iowa MiniMill Conducts PlantWide Energy Assessment Using a Total ... a grindingball plant in Duluth, Minnesota; ...

A cement mill (or finish mill in ... The grinding action employs much greater stress on the material than in a ball mill, ... The energy efficiency of this process is ...

Thermal Energy Audit of Kiln System in a Cement ... Energy audit, Waste heat recovery. Thermal Energy Audit of Kiln System In A ... (CM15) are of ball mill type and ...

WhatsApp)

WhatsApp)